Coating + Insulation + Waterproofing + Auxiliary Materials

Coating + Waterproofing + Auxiliary Materials

Coating + Insulation + Waterproofing + Auxiliary Materials

Coating + Waterproofing + Auxiliary Materials

Coating + Insulation + Waterproofing + Auxiliary Materials

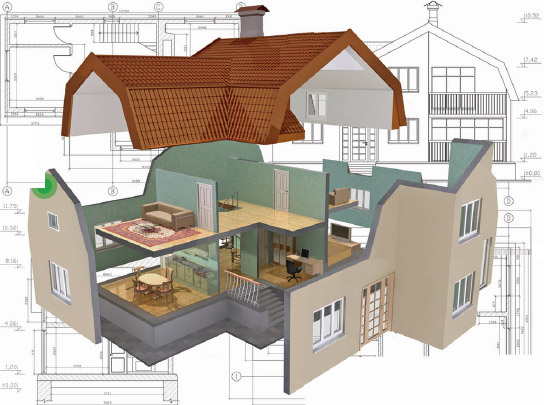

Among these, the most widely used is the external wall external insulation energy-saving technology, which has relatively high performance requirements for the thermal insulation system, necessitating a scientifically and reasonably designed approach.

Provides one-stop services for thermal insulation integrated systems nationwide.

Provides and ensures full-process services including auxiliary materials, insulation materials, finishes (or waterproof materials), and construction, thereby maximizing the quality assurance of the thermal insulation integrated system.

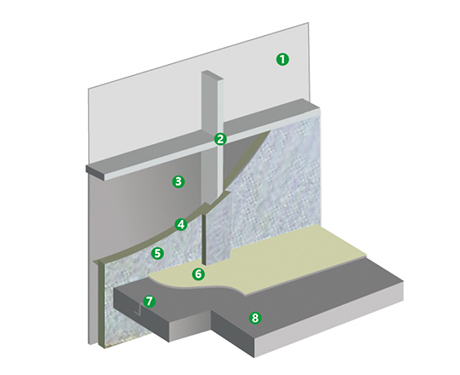

The external wall insulation system is one of the most mature and widely used energy-saving technologies abroad, and it is currently the most popular method of building insulation in China. Compared with internal wall insulation and prefabricated insulation, the external wall insulation system eliminates the generation of cold and hot bridges. Therefore, the external wall insulation system has become the main application method in passive ultra-low energy consumption buildings. External wall insulation integrated system designed by 3Trees includes adhesive mortar, high-quality insulation board, high-strength alkali-resistant fiberglass mesh cloth, flexible finishing mortar, matching flexible waterproof putty, and finishing (paint, decorative mortar), and possess excellent resistance to cracking, impact, and weathering.

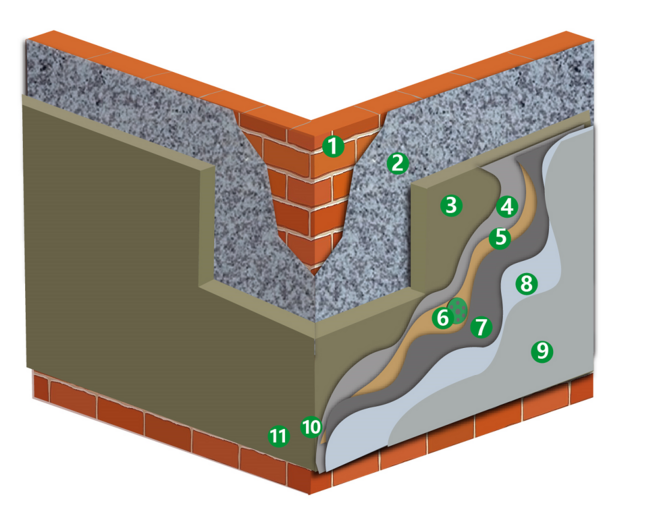

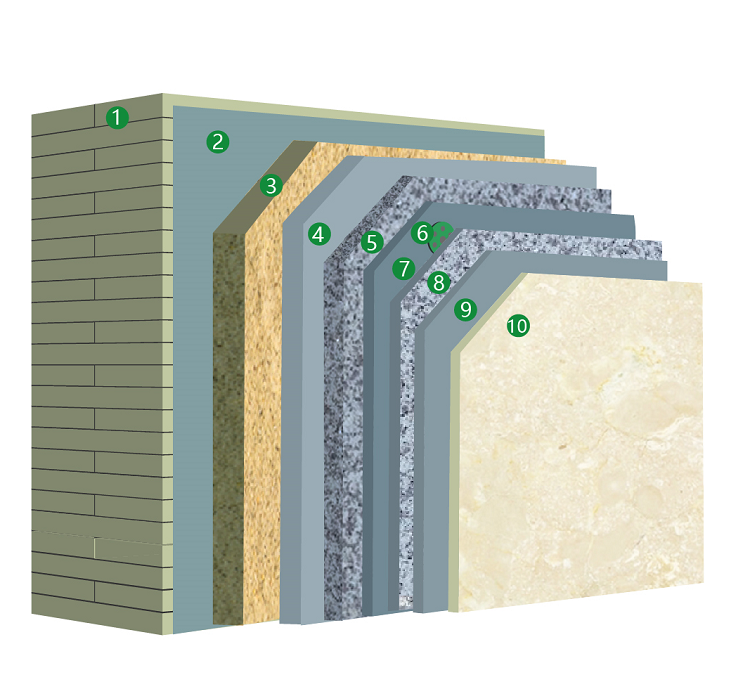

Rock Wool Board (series) External Wall External Insulation Integrated System

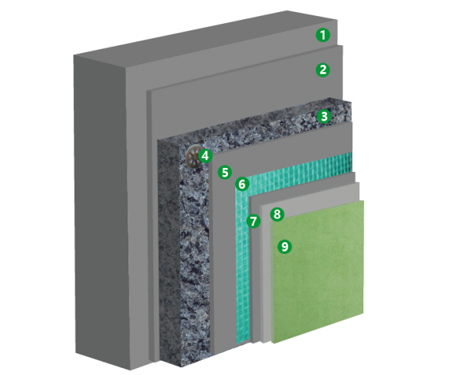

Phenolic Board (series) External Wall External Insulation Integrated System

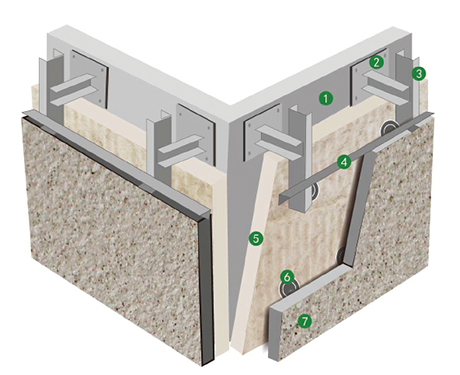

| No. | Rock Wool Board System (coated finish) | |

|---|---|---|

| Name | Description | |

| 1 | Substrate Wall | Includes reinforced concrete base, hollow block base, sintered brick base, aerated block base, etc. |

| 2 | Special Bonding Mortar for Rock Wool Board | High bonding strength and good workability. |

| 3 | Rock Wool Board/Strip | Rock Wool Board: Tensile strength ≥ 15KPa, Cotton Strip (vertical wire): Tensile strength ≥ 150KPa, Acidity coefficient ≥ 1.8, produced by the pendulum method. |

| 4 | Special Rendering Mortar for Rock Wool Board | High bonding strength and good crack resistance. |

| 5 | Alkali-resistant Glass Fiber Mesh Cloth | Surface treated with high molecular material, excellent alkali resistance. |

| 6 | Anchors | High strength and good toughness. |

| 7 | Special Rendering Mortar for Rock Wool Board | High bonding strength and good crack resistance. |

| 8 | Alkali-resistant Glass Fiber Mesh Cloth | Surface treated with high molecular material, excellent alkali resistance. |

| 9 | Special Rendering Mortar for Rock Wool Board | High bonding strength and good crack resistance. |

| 10 | Coating Finish | Includes Tiancai stone, real stone paint, texture paint, latex paint, etc. |

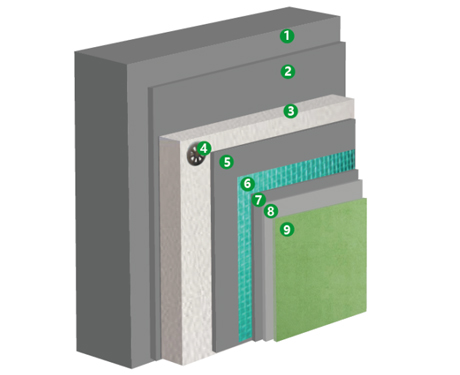

Graphite Polystyrene Board Insulation System is suitable for insulation and energy-saving requirements in different climatic regions of China. It can be applied to masonry structures made of reinforced concrete, concrete hollow blocks, sintered common bricks, sintered porous bricks, autoclaved fly ash bricks, or slag bricks. This system is designed for use in passive, nearly zero-energy consumption building exterior wall insulation, and is applicable to new construction, expansion, renovation, or the exterior wall insulation of existing industrial and civil buildings.

Extruded Polystyrene Board System is used for thermal insulation and energy-saving requirements in different climate zones in China, for masonry structures made of reinforced concrete, concrete hollow blocks, sintered ordinary bricks, sintered porous bricks, aerated concrete blocks or slag bricks. It is suitable for passive and nearly zero energy consumption external wall insulation of new, expanded, renovated or existing industrial and civil buildings. It is also suitable for energy-saving renovation of old building exteriors with old ceramic tiles, mosaics, water-based coatings, oil-based coatings, and other finishes.

| No. | Phenolic Board Series System | |

|---|---|---|

| Name | Instructions | |

| 1 | Base Wall | |

| 2 | Special Bonding Mortar for Rock Wool Board | High bonding strength, good workability |

| 3 | Polystyrene Board | Molded polystyrene board, graphite polystyrene board |

| 4 | Anchors | Select and use as needed |

| 5 | Special Plastering Mortar for Polystyrene Board | High bonding strength, good crack resistance |

| 6 | Alkali-resistant Fiberglass Mesh | High strength, good toughness |

| 7 | Special Plastering Mortar for Polystyrene Board | High bonding strength, good crack resistance |

| 8 | Flexible Waterproof Putty | Good flexibility, good waterproof performance |

| 9 | Coating Finish | Including Tiancai stone, real stone paint, textured paint, latex paint, etc. |

*Note: if a decorative mortar is used as the finishing layer, there is no need for a putty layer, which reduces the construction process and saves costs.

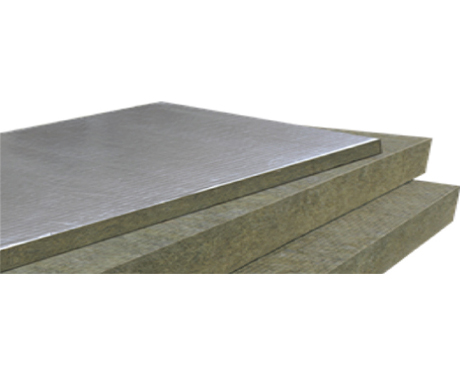

The main core material of the internal wall insulation integrated system is the eco-friendly insulation rockwool, which is free of formaldehyde and has a low thermal conductivity.

This product is made with a proprietary formula and special production process, so it does not contain any toxic and harmful substances such as formaldehyde, and its multiple indicators lead the industry and exceed international standards.

Not only does it achieve fire prevention, insulation, and sound insulation, but it also solves indoor and outdoor air pollution problems, fully meeting the high requirements of modern building decoration for indoor environments.

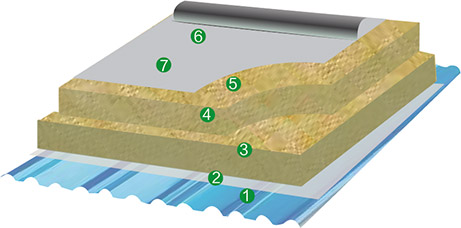

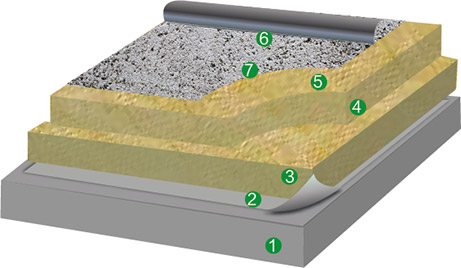

The high-strength rockwool board and graphite polystyrene board roof insulation and waterproof integrated system is designed and developed for various flexible waterproof roof systems. It is an integrated system that combines insulation, waterproofing, sound insulation, and noise reduction functions.

It has good compressive and point load resistance, which can meet the needs of carrying the weight of personnel and related equipment during roof system construction and maintenance, while maintaining stable insulation, waterproofing, sound insulation, noise reduction, and fire protection effects.

It is mainly used in green roofs, flexible waterproof roofs, and other new, expanded, or existing buildings, and is used in conjunction with perforated metal sheets.

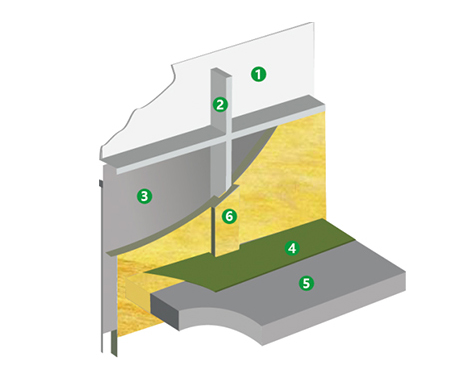

The curtain wall fireproof insulation rock wool board Integrated System is designed specifically for various curtain wall systems, offering advantages such as higher fire resistance temperature, higher melting point, and longer fire resistance duration.

The specialized rock wool board is not only used for fire and smoke prevention in the gaps between curtain walls and floor slabs, as well as between curtain walls and partition walls, but it can also be used for fire sealing in other building crevices, including around various pipes penetrating walls or floor slabs.

The composite rock wool board with fireproof aluminum foil on its upper and lower surfaces enhances its smoke prevention capability, providing better fire resistance effects.

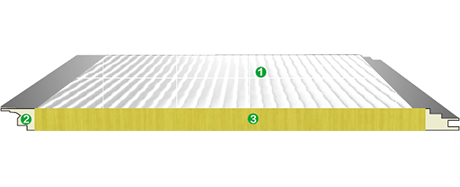

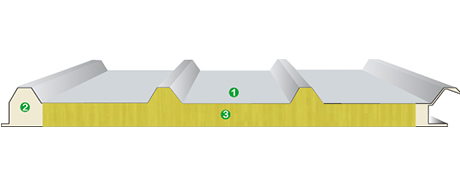

The main core material of the metal sandwich panel insulation system is the special rock wool strip designed for sandwich panels. When used within the metal panels, it can naturally settle without the need for pleating. Its strip structure enhances the overall system's tensile strength and exhibits excellent structural characteristics.

Moreover, its lightweight nature significantly reduces construction costs. Additionally, its feature of easy cutting simplifies installation, thereby increasing efficiency and saving time.

High-quality rock wool material also provides fire resistance, thermal insulation, and sound insulation, meeting the insulation requirements of various metal sandwich panel applications.